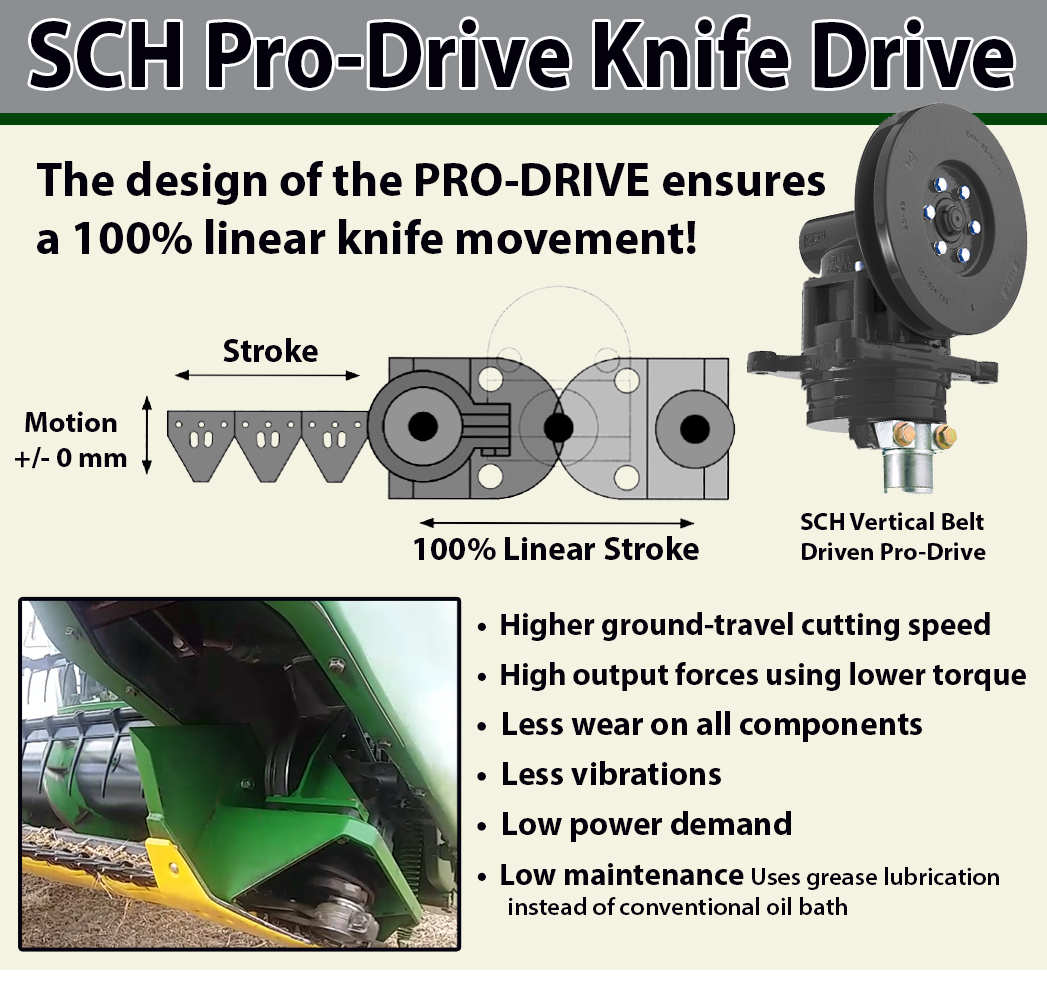

PROBLEM: Most knife drives lose stroke length and force.

SOLUTION: The SCH Pro-Drive's planetary gear system is in rotation at all times. This produces a 100% linear knife movement, compared with wobble boxes or other oscillating and pendulum drives.

Advantages of SCH Pro-Drive Compared to Comventional Cutterbar Knife Drives:

• Higher Ground-Travel Cutting Speed

• High Output Forces Using Lower Torque

• Low Maintenance Uses grease lubrication instead of conventional oil bath

• Less Wear on all Components

• Less Vibrations

• Low Power Demand

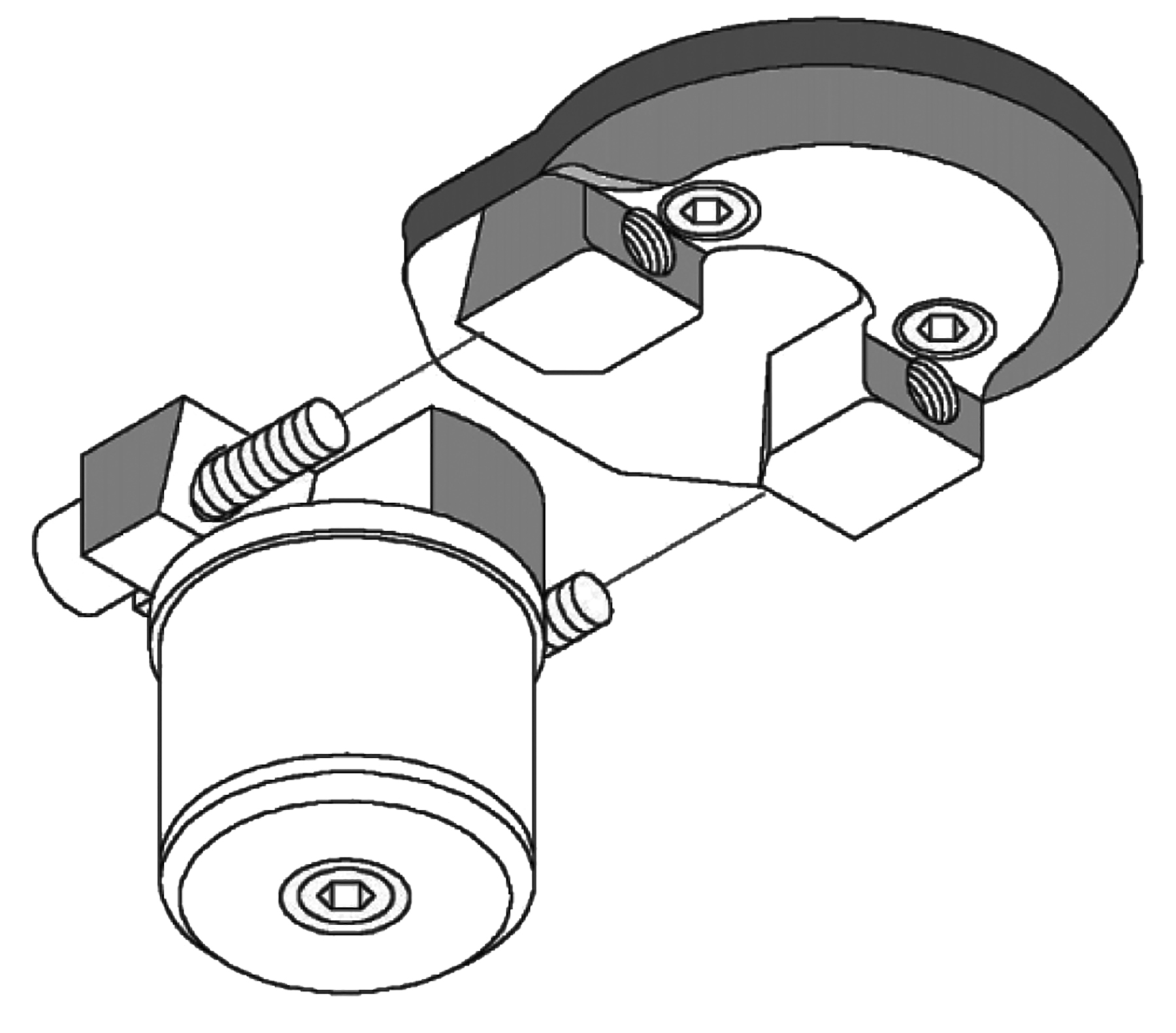

Makes Changing Knives, Even in the Field, a Breeze

The SCH engineers have devised a brilliant method of attaching the knifehead to the drive that is a major advancement. Designed as a trapezoidal claw, the connection is easy and accurate. No bolts to line up, no bearings to adjust or shim, no fear that dirt might get into bearings, bushings, etc. Makes changing knives even in the field a breeze.

Higher Ground-Travel Cutting Speeds:

Testimonial from Huron County, Michigan: “I bought an Sch ProDrive knife drive for my 1020 Header this spring. Put 500 acres on it and couldn't be happier. Ground Speed was faster by .5mph to 1mph even with worn out dull guards. I can’t wait to see what it will do with brand new knives and guards next fall.”

All SCH Pro-Drive Conversion Kits Include:

-

SCH Pro-Drive, vertical, 85mm (3.3") stoke

-

Drive pulley for SCH Pro-Drive

-

Mounting bracket for SCH Pro-Drive

-

Knifehead

-

Extra nylon ring for knifehead

Warranty: SCH Pro-Drives have a 1 year warranty on parts and labor from date in service.

Comparison of SCH Pro-Drive to conventional cutterbar knife drives

Almost all conventional cutterbar knife drives in combine harvesters have a knife stroke of between 3” and 3-1/3”. When a crop that is difficult to cut loads the cutting knife, the knife rarely travels the full length of the stroke. A considerable amount of the stroke is lost in deflecting gear housings, gear brackets, ball and socket joints and installed wobble boxes. Drives have been tested in which the stroke has fallen to 2-1/2” under load. The knocking and shaking this produces in the cutterbar is known to almost every expert in the field. It gives the impression that dull sections are being used.

The SCH Pro-Drive high performance cutterbar knife drive eliminates all these problems. Built using planetary gears, these drives produce an absolutely linear knife movement when compared with wobble boxes or other oscillating and pendulum drives. The gears are in exact alignment with the knife. This means there is no need for reversing or oscillating levers, which causes the loss of stroke in other drives. The full length of the stroke generated by the planetary gears is transmitted to the knife. The SCH Pro-Drive high performance knife drives can be driven either horizontally or vertically.